What is the AI and CV in manufacturing?

Computer vision in manufacturing is streamlining the use of visual data to make faster and better decisions. Factories become safer, and the production quality increases when manufacturers use insights shared by computer vision systems. With advancements in machine learning algorithms, increased computational power, and the availability of vast amounts of data, ocr conversion services and CV are revolutionizing traditional manufacturing processes. This article explores the various applications and benefits of AI and CV in the manufacturing sector.

The global computer vision market in 2020 was $11.32 billion and is expected to grow at a CAGR (Compound Annual Growth Rate) of 7.3% by 2028. The industrial segment was responsible for around 51% of the market revenue. Computer vision in a range of manufacturing processes contributed more than half the total global share. The Asia Pacific region had a high adoption rate and contributed 40% of the revenue in the same year.

But how is computer vision used in the manufacturing industry? With more and more manufacturers planning to adopt computer vision and Industry 4.0, how do they intend to change their systems and processes? Let’s take a look.

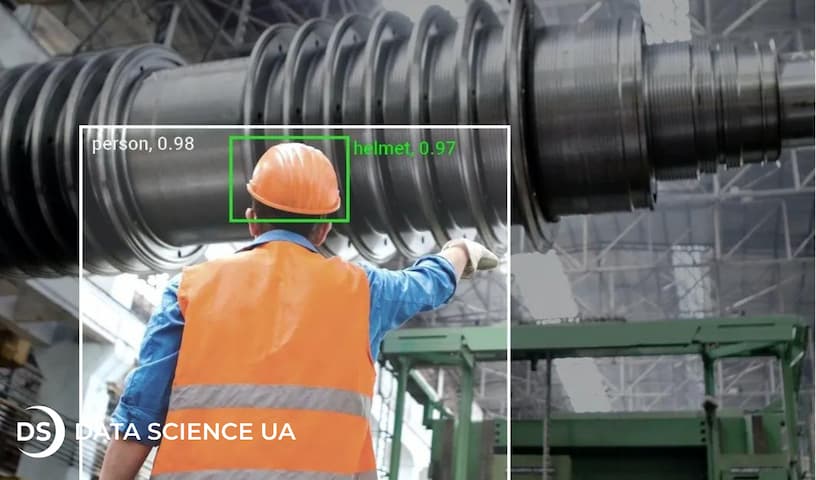

Worker Safety and Automation

With the deep AI expertise of the company who can implement custom computer vision development services, we deploy state-of-the-art algorithms and advanced machine learning techniques to optimize operations, reduce downtime, and streamline processes. Also, we dive deeper into the realm of computer vision, enabling visual inspection that surpasses human capabilities, ensuring precision and accuracy in every step of the production line, and reducing the number of accidents in heavy industry and manufacturing companies.

We develop intelligent systems that can identify patterns, predict anomalies, and provide real-time insights. By leveraging this technology, heavy industry and manufacturing businesses can achieve remarkable improvements in operational efficiency, quality control, and resource allocation.

AI and CV can enhance safety by monitoring employee activities and alerting them to potential hazards. Computer Vision can detect unsafe behaviors or unauthorized personnel in restricted areas, triggering immediate warnings or automated safety measures. AI-powered robots and cobots (collaborative robots) equipped with CV systems can assist workers in performing repetitive or dangerous tasks, reducing the risk of injuries and increasing overall efficiency.

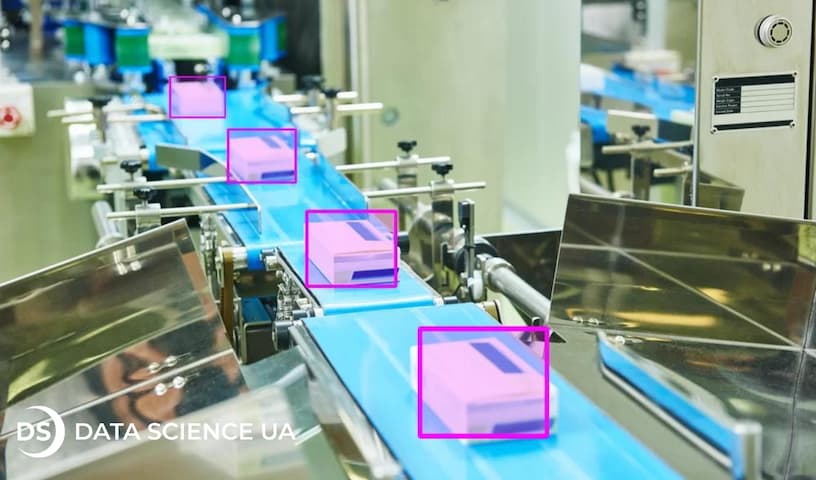

Quality Control and Inspection

Machine learning development stands behind many great advances in industrial automation. One of the most prominent achievements is the field of quality control.

In a lot of companies quality control is still a manual operation. However, although the human ability to visually inspect different objects is very high, subjectivity and fatigue resulting from performing repetitive tasks may result in human errors. By contrast, CV-based automated systems offer an effective solution for quality and process control, adding value to inspection operations due to enhanced productivity, the accuracy of the manufacturing processes, and reduction of operational costs.

A CV-based automated system includes a camera looking at a production line that captures images which are then algorithmically compared to a predefined image in order to detect defective objects. The application has found major adoption for the detection of imperfections, geometric inspection, packaging control, product classification, surface finish inspection, color and texture analysis, etc.

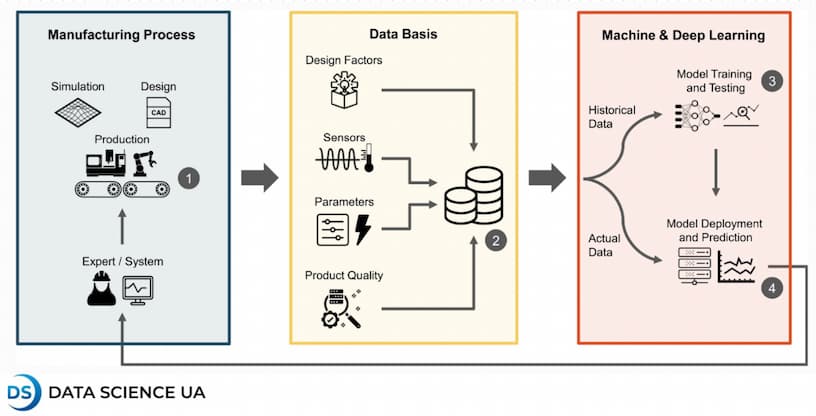

Predictive Maintenance

Another crucial area where AI and CV shine in manufacturing is predictive maintenance. By analyzing sensor data, video feeds, and historical maintenance records, data science development company can identify patterns and predict potential equipment failures. Computer vision can detect anomalies in machinery, such as unusual vibrations, temperature variations, or corrosion, enabling manufacturers to proactively schedule maintenance and prevent costly breakdowns. This predictive approach helps optimize equipment performance, reduce downtime, and extend the lifespan of assets.

Predictive quality solutions are built upon data from the manufacturing process. By extracting recurring patterns from the data and relating them to quality measurements, predictive quality enables the data-driven estimation of the product quality based on process data. The estimations serve as a decision-making basis for quality enhancing measures, such as adjusting the process parameters for avoiding rejects. The common approach to predictive quality includes four main steps: the formulation of the manufacturing process and target quality, the selection and collection of process and quality data, the training of a ML/DL model, and the use of the model for estimations as a basis for decisions. In this context, predictive quality mainly comprises methods for supervised ML.

Predictive quality approach: for a selected manufacturing process (1), relevant process and quality data is collected (2) and used as a basis for training a ML model (3). The trained model is used to perform quality estimations for decision support (4)

Production Optimization

AI and CV can optimize production processes by collecting and analyzing real-time data from various sources, including sensors, cameras, and production lines. Machine learning algorithms can identify bottlenecks, optimize workflows, and provide insights for continuous improvement. For example, computer vision systems can monitor assembly lines, identify inefficiencies, and suggest adjustments to improve productivity. AI algorithms can also predict demand patterns, optimize inventory management, and streamline supply chain operations.

Artificial Intelligence and Computer Vision are transforming the manufacturing industry by revolutionizing quality control, predictive maintenance, production optimization, worker safety, and product design. These technologies offer immense potential for increased efficiency, cost reduction, and improved product quality. Manufacturers that embrace AI and CV can gain a competitive edge in today’s rapidly evolving market. As AI and CV continue to evolve, their integration with manufacturing processes will become increasingly seamless, paving the way for a more productive and innovative future.