Table of Contents:

- What Is AI in Manufacturing?

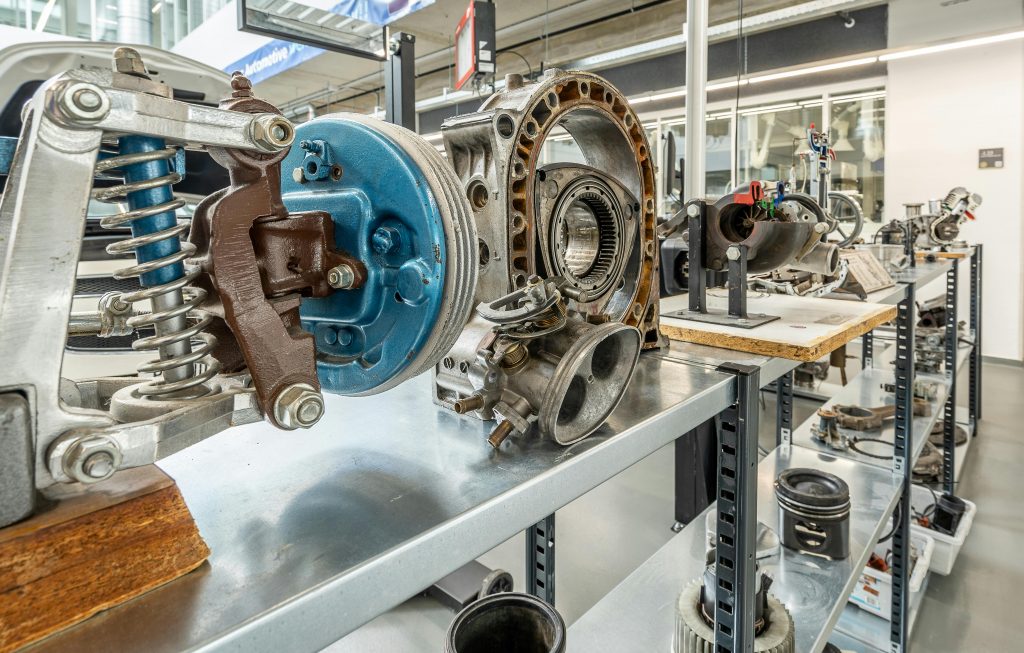

- Crucial AI Components Reshaping Manufacturing

- Significant Advantages of AI in Manufacturing

- AI in Manufacturing Examples

- Practical Instances of AI Implementation in Manufacturing

- How to Get Started With AI in Manufacturing?

- The Role of AI in Manufacturing Industry: Summary

- FAQ

AI in Manufacturing Examples: Everything You Need to Know

Artificial Intelligence in Manufacturing: Transforming processes across industries. Explore AI use cases at Data Science UA.

AI in Manufacturing: Examples and Use Cases

What Is AI in Manufacturing?

Artificial Intelligence (AI) in manufacturing uses tools like machine learning (ML) and deep learning (DL) to enhance how factories work. These tools help examine data, automate jobs, and make wise choices, resulting in greater efficiency, reduced costs, and improved product quality.

AI for manufacturing includes checking product quality automatically, predicting maintenance needs, and optimizing supply chains. Both large and small companies benefit from AI in manufacturing, making processes more efficient and productive. AI in factories involves using smart machines to perform tasks like assembly and quality checks.

Examples of AI in manufacturing include predicting machine failures, using deep learning for quality control, and employing robots for logistics. These AI use cases in manufacturing show how AI can transform the industry by improving efficiency and reducing waste.

In short, AI in manufacturing uses smart technologies to enhance production processes. Integrating AI is essential for future growth and innovation in the manufacturing sector.

Machine Learning (ML)

Machine learning (ML) is changing the manufacturing industry by making automation smarter and using predictive analytics. At ML development services: Machine Learning (ML), we use AI to improve everything in manufacturing, from production lines to supply chain management.

AI solutions in manufacturing make operations smoother and greatly increase productivity. For example, AI in factories uses ML algorithms to predict machine problems before they happen, reducing downtime and keeping production going. Also, AI in the manufacturing industry uses advanced analytics to make the best use of resources, cutting down waste and boosting efficiency.

Examples include real-time inventory management and quality control systems that adjust settings based on AI insights. This high level of automation ensures high-quality production with fewer mistakes. Furthermore, AI use cases in manufacturing show how AI can transform operations with better predictive maintenance and optimized energy use, leading to lower costs and better sustainability.

Using artificial intelligence in the manufacturing industry means adding AI-driven solutions like predictive maintenance, smart manufacturing processes, and AI-enhanced logistic operations. These tools not only prevent equipment failures but also ensure the best performance and use of resources, making AI solutions for manufacturing essential for modern factories.

Deep Learning (DL)

Deep learning (DL) is a part of machine learning (ML) that uses special networks with many layers to study complex data patterns. DL can be used for improved quality control, spotting unusual patterns, and predicting future maintenance needs. This leads to improved efficiency and reduced costs in the application of artificial intelligence in the manufacturing industry.

There are many ai in manufacturing examples showcasing how it work together to improve processes. For instance, artificial intelligence for manufacturing helps in monitoring production lines in factories using ai to ensure products meet quality standards. Another ai use case in manufacturing is the detection of equipment failures before they happen, which is a practical application of predictive maintenance.

The use of AI in manufacturing also extends to optimizing supply chains and managing inventory. Specific examples of artificial intelligence in the manufacturing industry include robots collaborating with humans on assembly lines, thereby increasing productivity and safety. Examples of ai in manufacturing show how artificial intelligence applications in manufacturing are transforming traditional methods.

AI solutions provide numerous advantages, including waste reduction, improved precision, and faster production times. The ai application in manufacturing has proven to be a game-changer, providing innovative ai solutions in manufacturing processes, leading to more sustainable and efficient production methods.

Autonomous Objects

Robots and drones, known as autonomous objects, are becoming increasingly common in the AI for manufacturing field. These advanced devices take on tasks that are repetitive, dangerous, or need high precision. By leveraging artificial intelligence for manufacturing, they can work independently, reducing the need for human intervention and boosting overall production efficiency.

For example, in AI in factories, robots are assembling products with incredible accuracy, and drones are used for monitoring and inspecting equipment.

Using AI in manufacturing extends to many different areas. Robots handle hazardous materials, and drones survey large areas, showing how artificial intelligence applications in manufacturing are changing the industry.

Adopting AI solutions for manufacturing brings many benefits, such as better safety, higher precision, and faster production speeds. Overall, AI is transforming how industries operate, making them more productive and safer.

AI for manufacturing offers numerous benefits, making production more efficient and precise. By automating repetitive and complex tasks, artificial intelligence reduces human error and cuts costs. In the AI in manufacturing industry, predictive maintenance helps minimize downtime, while real-time data analysis fine-tunes production.

Examples include robots on assembly lines and AI-driven quality control systems. These AI solutions not only improve product quality but also speed up innovation and ensure safer work environments. The use of AI in manufacturing is transforming the industry, driving continuous improvements and delivering significant advantages.

Predictive Maintenance

By studying data from sensors, AI can predict when equipment will fail before it actually does. This helps to decrease stoppages and cut down on maintenance expenses. This method also makes machinery last longer.

In the AI in manufacturing industry, predictive maintenance illustrates how AI and manufacturing can work together seamlessly. By using artificial intelligence applications in manufacturing, companies can boost efficiency and reliability. This innovative AI application in manufacturing is transforming traditional maintenance practices and delivering significant benefits.

Intelligent Quality Assurance

These systems inspect products in real time, detecting defects to ensure that only the highest quality products reach the market. This use of AI in the manufacturing industry not only boosts customer satisfaction but also cuts down on costs related to returns and repairs.

In the world of manufacturing and AI, these systems are standout examples of AI in manufacturing. They are key AI solutions for manufacturing that enhance the efficiency of production processes. By incorporating AI, companies achieve top-notch quality control. These examples highlight the profound impact, setting new standards for quality and operational excellence.

Amplified Efficiency

AI is making a big impact in manufacturing by improving how production schedules are planned, making operations more efficient, and cutting down on waste. Advanced algorithms sift through production data to spot bottlenecks and suggest ways to make things better. This teamwork is really boosting productivity. These AI solutions result in smoother operations and smarter use of resources. By bringing AI into their manufacturing processes, companies are achieving higher efficiency and sparking innovation. These improvements are raising the bar for operational excellence in the industry.

Innovative Design Generation

AI is changing the game in the manufacturing industry by helping design teams come up with innovative product designs quickly and efficiently. By using AI, designers can input specific requirements and performance criteria, and the AI system generates creative design options. This use of AI in manufacturing speeds up the entire development process, leading to more innovative and effective products.

In the realm of AI for manufacturing, this application is a great example of how artificial intelligence can aid in manufacturing. It shows how AI isn’t just about improving production lines but also enhancing the creativity and efficiency of the design phase.

Optimized Inventory Management & Demand Prediction

AI-driven inventory management systems are revolutionizing the way companies handle stock in the manufacturing industry. These systems use AI to predict demand trends accurately, helping businesses maintain optimal stock levels. This means they can keep just the right amount of inventory, reducing waste and lowering the chance of running out of stock. This application of AI in manufacturing leads to better use of resources and enhanced customer service. In the world of AI and manufacturing, this is a standout example of AI solutions in manufacturing that streamline operations. By integrating AI, companies can ensure they always have just the right amount of inventory on hand. These systems are showing how artificial intelligence can lead to smarter and more efficient business practices.They are great AI use cases in manufacturing in action, setting new standards for how well operations can run and how happy customers can be in the manufacturing and AI field.

Tailored Factory Configurations

AI is transforming the manufacturing industry by enabling manufacturers to design customized factory layouts that maximize efficiency and adaptability. This is incredibly useful in industries with rapidly changing production requirements. By using AI , companies can swiftly adjust their setups to meet new demands without sacrificing performance.

This application of AI is a great example of how artificial intelligence can enhance manufacturing operations, making them more flexible and efficient. These AI solutions not only cater to current needs but also prepare businesses for future challenges, demonstrating the significant benefits of integrating AI into manufacturing processes.

Food Quality and Labeling

AI systems revolutionize food quality and labeling checks, ensuring compliance with regulations and building consumer trust while minimizing waste and contamination risks. By analyzing images and verifying labels and expiration dates, AI enhances accuracy and reduces human contact during events like the COVID-19 pandemic, with costs comparable to traditional methods.

Steel Quality Inspection

AI-driven inspection systems elevate steel production quality by identifying flaws, minimizing waste, and streamlining defect detection and classification processes. These systems require labeled images of both good and defective steel for effective real-time analysis, promising significant benefits in defect reduction and cost savings compared to conventional sampling methods. Major steel companies are swiftly adopting this technology, poised for widespread implementation in the coming years.

Advanced Technology Manufacturing

AI plays a pivotal role in advancing manufacturing technologies such as 3D printing and nanotechnology, optimizing efficiency and fostering innovation despite the complexities of diverse product lines. Leveraging labeled examples of good and bad products, AI enhances defect detection capabilities, ensuring higher product standards and reliability for industries like aerospace.

Quality Control and Defect Detection

AI drives quality control improvements in manufacturing by swiftly identifying defects and enhancing production efficiency. Utilizing labeled images from video feeds, AI supplements human inspection efforts, allowing skilled workers to focus on critical tasks while ensuring top-notch product quality. With a majority of manufacturers investing in AI for quality control, its applications span across various industries like automotive and pharmaceuticals, ensuring consistent product excellence.

Predictive Maintenance

AI empowers predictive maintenance strategies, preempting equipment failures through timely interventions and cost-effective maintenance schedules. By analyzing sensor data, real-time metrics, and environmental factors, AI detects potential issues early, optimizing machine performance and minimizing downtime. From forecasting maintenance schedules to identifying faulty parts, AI-driven predictive maintenance ensures seamless and uninterrupted production processes with substantial long-term cost savings.

Process Automation

AI is transforming manufacturing by automating repetitive or complex tasks, making operations faster and more accurate while freeing up human workers for more detailed tasks. The amount of data it needs depends on task complexity, such as requiring images and instructions for sorting items in a warehouse. This automation not only makes things faster but also keeps them accurate all the time. Examples of AI in manufacturing include making processes smoother, spotting problems, organizing warehouses, and using smart accounting systems.

Design Improvement

AI plays a big role in making product designs better, considering things like materials, size, and how the product will be made. It helps businesses find the best design faster, looking at lots of options that humans might miss. This is super helpful because sometimes there are ways to make things even better that we didn’t think about before. AI can even learn from past tests to improve future designs. For example, it’s been used to make lighter parts for airplane cabins. It’s not just for making gadgets, though; it can also help with making better food, drugs, or city plans.

Demand Prediction

AI helps businesses estimate future sales by analyzing past sales data, prices, and marketing efforts. This helps them plan production and inventory levels more effectively, reducing wasted resources and ensuring products are available when customers need them. It’s effective and can manage a lot of data, which helps make customers happier by accurately predicting what they will want. For example, it can help set prices and decide when to introduce new products based on what’s currently popular in the market.

Food Waste Reduction

AI technology is helpful in reducing food waste by analyzing various factors like customer demand, sales data, and economic conditions. By knowing these details, businesses can plan their production and stock better, reducing the amount of extra food that might be wasted. This not only saves money but also benefits the environment by minimizing waste. For instance, it can guide businesses in ordering the perfect amount of ingredients to prevent having excess.

AI Integration in Logistics

In modern logistics, using AI has completely changed how things are done. AI serves as a powerful tool, looking at lots of data to make every part of the supply chain smoother. It helps companies predict what customers will want, find the best delivery paths, and handle problems before they happen. By using AI technology, logistics companies work more efficiently, spend less money, and make customers happier. It’s a key improvement that helps businesses perform better and stay ahead of the competition.

AI-Driven Supply Chain Management

AI-powered supply chain management is very important for businesses. It helps them understand what customers need and speed up their operations. With AI, companies can plan more effectively, prevent delays, and deliver products to customers quickly. It’s all about ensuring everything runs smoothly and keeping customers satisfied. Using AI in supply chain management helps businesses stay ahead of the competition and be more successful.

Streamlined IT Operations

Streamlined IT operations make everything smoother in the tech world. It’s like having a smooth-running machine that operates without any issues. With streamlined IT, tasks are completed more quickly, problems are resolved faster, and everyone remains content. It’s all about ensuring everything functions smoothly and efficiently. Streamlining IT operations allows businesses to keep pace with rapid technological advancements and stay competitive.

Convergence of IoT and AI

The integration of IoT and AI is a significant development in technology. It’s akin to forging a powerful partnership between two proficient allies. Together, IoT and AI empower devices to communicate, learn, and execute tasks autonomously. This collaboration enhances efficiency and effectiveness in various applications. As IoT and AI converge, they propel industries towards a future of heightened productivity and seamless connectivity.

Efficient Warehouse Management

Efficient warehouse management is a key factor in business success. It’s like orchestrating a complex dance where every move is carefully planned. With effective management, warehouses operate seamlessly, inventory is easily accessible, and shipments are dispatched promptly. It’s all about maintaining order and precision to meet demands efficiently. Efficient warehouse management not only saves time and money but also ensures customer satisfaction remains high.

Innovation in Product Development

Effective product development innovation is crucial for companies. It involves exploring new ideas and methods to create valuable products. Through innovation, businesses can develop unique offerings that meet customer needs and stand out in the market. It’s about fostering creativity and staying ahead of the competition. Innovation in product development is a cornerstone of success for companies striving to meet evolving consumer demands.

Connected Factories with AI

AI is revolutionizing factories, enhancing their capabilities and efficiency. It involves integrating AI technology into factory operations, enabling machines to communicate, identify issues in advance, and autonomously address them. This integration optimizes production processes, leading to improved productivity and reliability. Connected factories with AI empower businesses to streamline operations, reduce costs, and enhance the quality of goods manufactured.

Efficient Paperwork Handling

AI helps businesses manage paperwork better. It makes tasks like sorting, filing, and processing documents easier and faster. With AI, paperwork is handled quickly and accurately, saving time and reducing mistakes. This technology ensures that administrative work runs smoothly, letting businesses focus on their main activities. Efficient AI-powered paperwork handling improves productivity and makes things simpler for everyone.

Practical Instances of AI Implementation in Manufacturing

In manufacturing, AI is being put to practical use. It helps machines operate more efficiently by predicting problems in advance and maintaining consistent product quality. With AI, manufacturing processes run smoother, saving costs and ensuring businesses operate seamlessly.

Toyota Collaborates with Invisible AI

Toyota has teamed up with Invisible AI to transform its manufacturing processes. Invisible AI specializes in using artificial intelligence to enhance industrial operations. By incorporating Invisible AI’s advanced technology into its production lines, Toyota aims to boost efficiency and product quality.

Invisible AI’s real-time monitoring technology quickly detects and addresses issues, helping Toyota optimize its manufacturing, reduce waste, and maintain its industry-leading standards. This partnership highlights Toyota’s commitment to innovation and continuous improvement, reinforcing its position as a leader in the automotive sector. Through this collaboration, Toyota continues to deliver superior products to its customers.

This partnership serves as a perfect example of AI in manufacturing, showcasing how smart technology can significantly benefit industrial settings.

Suntory PepsiCo Streamlines Its Quality Control in Production

Suntory PepsiCo has improved how it checks the quality of its drinks during production. By using new technology, specifically AI in manufacturing, to monitor production and automate important checks, the company can now find and fix problems faster and more accurately. For example, AI systems can detect inconsistencies in bottle filling levels and identify packaging defects in real-time. This new method reduces waste and delays, making sure every drink is of high quality before it reaches customers. Suntory PepsiCo shows its dedication to excellence with these improvements in quality control.

How to Get Started With AI in Manufacturing?

They possess the expertise and resources to assist you in effectively implementing AI solutions. They have the expertise and resources to help you implement AI solutions effectively. Check out our services at AI Development Company to learn more.

The Role of AI in Manufacturing Industry: Summary

Artificial intelligence (AI) is changing the manufacturing industry by making it more efficient, cutting costs, and bringing new solutions. AI helps automate tasks, improve operations, and check product quality.

AI also helps maintain high quality through advanced monitoring systems. This makes production lines smarter and more efficient. By working with an AI development company, manufacturers can use AI effectively to stay competitive and meet market needs.

Explore AI in manufacturing to see how it can improve your operations, ensuring you deliver high-quality products and stay ahead in the industry.

FAQ

Will AI Shape the Future of Manufacturing?

AI is set to revolutionize the industry by making production processes smarter and more efficient. With AI, manufacturers can automate tasks, predict equipment failures, and optimize operations. This brings about substantial gains in efficiency and reductions in expenses.

How Will AI Affect Manufacturing?

Artificial intelligence in the manufacturing industry will enhance quality control, reduce downtime through predictive maintenance, and optimize supply chain management. These solutions will result in higher efficiency, better product quality, and lower operational costs.

Could AI Enhance Product Quality and Minimize Defects in Manufacturing?

Yes, AI can significantly improve product quality and minimize defects by providing real-time monitoring and analysis during production. AI applications in manufacturing identify anomalies and defects at an early stage, guaranteeing that only top-quality products make it to the market.